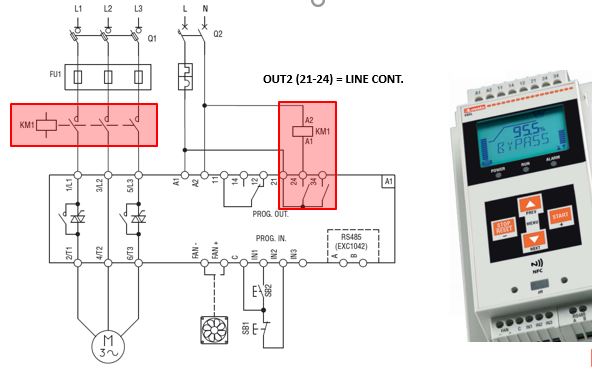

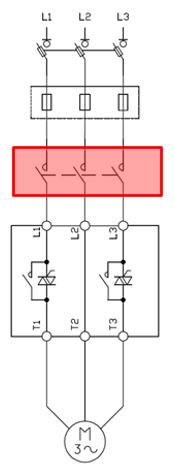

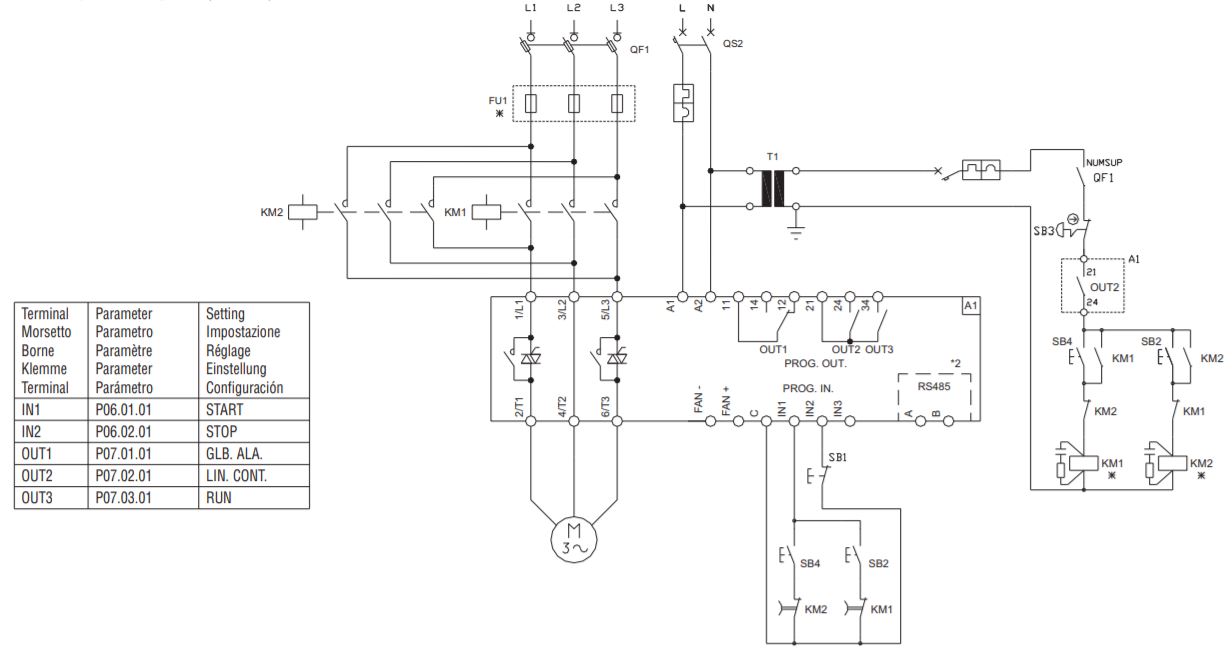

It is a contactor installed upstream the soft starter to warrant a galvanic separation between the power supply line and the motor when the motor is not in use (stop).

The presence of the line contactor is extremely important for the following purposes:

1.Safety of the personnel: it removes the voltage on the motor side when the motor is not in use. The leakage currents through the thyristors may lead to dangerous voltages on the load side when the soft starter is supplied.

2.Protection of the internal thyristors: the line contactor isolates the soft starter and protects the internal thyristors from any problems present on the network, like severe voltage spikes on the incoming line, such as lightning strikes or downed power line, etc… à possible consequences: damage of the thyristors (short circuit).

3.Disconnect the soft starter from the supply in case of fault:

−without a line contactor the soft starter can only detect a fault condition (e.g., thyristors shorted, bypass relay stuck, etc…) and provide signalization using fault relay (if available) but is not able to stop the motor despite the stop command from the logic input.

−there must be a device that will react on fault signal and stop the motor!

For the reasons outlined above, the presence of the line contactor on soft starters is mandatory. The standard prescribes only requirements for the protection against short circuit and protection of the installation. But for the reasons just given, a line or isolation contactor is strongly suggested even if not mandatory.

____________________________________________________

Other information on this topic

Visit the website page dedicated to contactors. Check out our video on BF series

Visit the website page dedicated to ADXL… series soft starters and check out related videos